37, 000 Professional Viewers Watched Douson Product Marketing Promotion Event

Release time:

2020-07-14 17:46

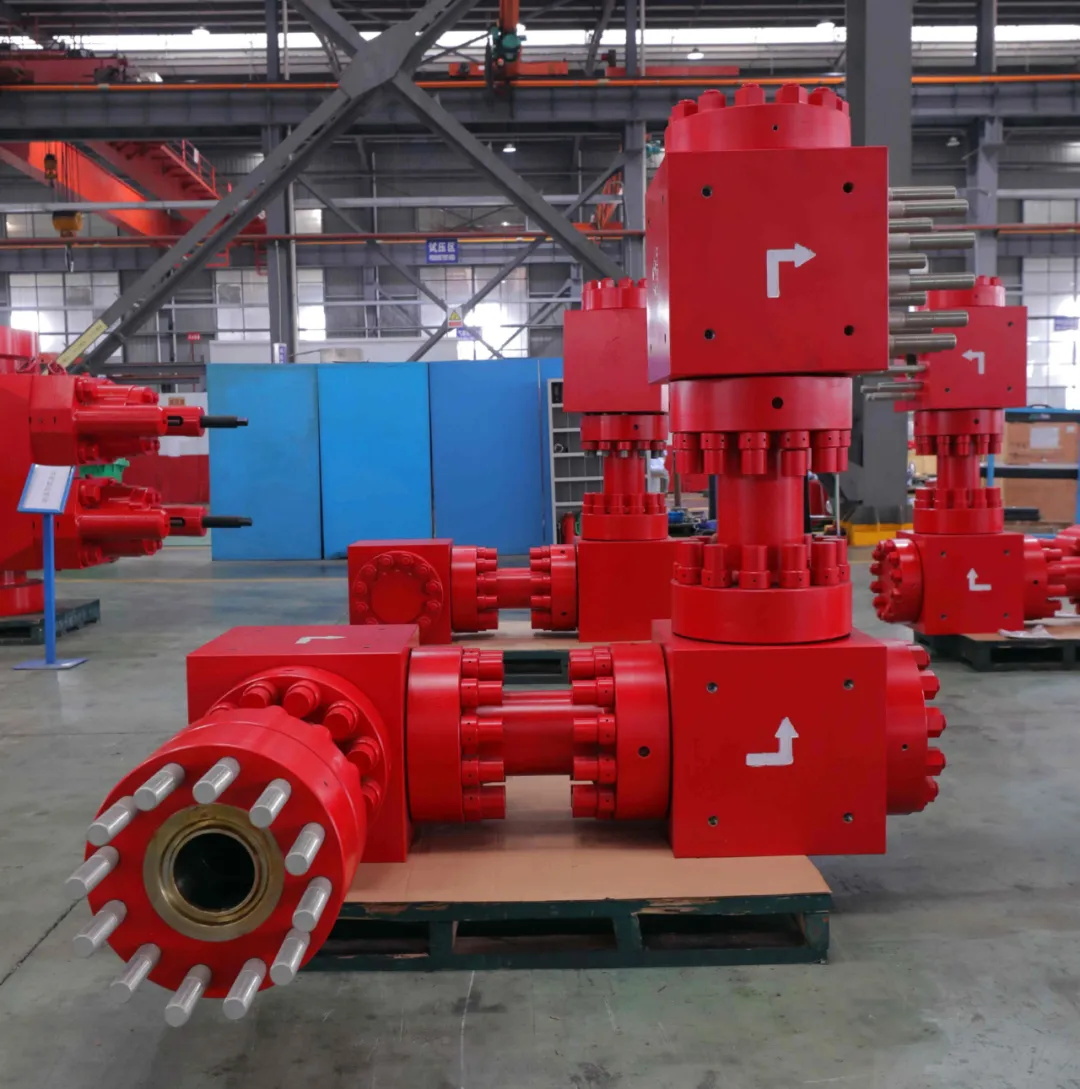

In the past week, Douson Co., Ltd. appeared at the Cippe Precision Marketing Promotion Conference - a special session on high-pressure fluid series products. This online promotion event is the first time that Douson has demonstrated 6A well control equipment to users at the company's site since its establishment. Douson showed the company's most technical level and market value equipment.

According to statistics from cippe background, this online presentation attracted more than 37,000 professional viewers to watch online. Open the recorded video below to learn more:

|

140MPa Ultra-high Pressure Desander

3-1/16'' 140MPa composite high-efficiency multifunctional desander: it is the key equipment for separating solid particles in fracturing flowback fluid, mainly by cyclone to remove sand. It is composed of components, sand storage cylinder and electric control system. The cyclone desanding component and the sand storage tank adopt an integrated design, and there are only three external interfaces, which are convenient for on-site connection. The cyclone desanding component integrates cyclone and filtration, and has stable working performance; the sand storage tank can store the separated solid particles for a short time; the electric control system has automatic control function, which greatly reduces the operation time of the gate valve in the desander.

Conventional Desander

3-1/16'' 105MPa Desander, the main component is the cyclone desander assembly, which can carry out continuous sand removal operation. The desander adopts a lightweight design, and the overall weight is reduced by about 40%, which has great advantages in transportation and on-site installation. In addition, the installation height of the main valve in the desander is low, and the operator can manually operate all the main valves standing on the ground.

7'' 140MPa Surface Fracturing Manifold

The working pressure is 140MPa, and the nominal bore diameter is 180mm. It has the characteristics of good sealing and high operation efficiency, and meets the requirements of multi-well, high-pressure, and large-displacement fracturing operations in oil fields.

7'' 140MPa Ultra-high Pressure Large-diameter Hydraulic Valve

It is a key component of the fracturing manifold, and the hydraulic control switch is convenient for remote operation. The highest performance level of the valve is PR2.

5'' 105MPa Fracturing Manifold

Through the application of the eight-channel ball head and the "one-in, three-out" interface design, three oil and gas wells can be fractured at the same time, with high work efficiency and compact structure design, effectively saving on-site operation time.

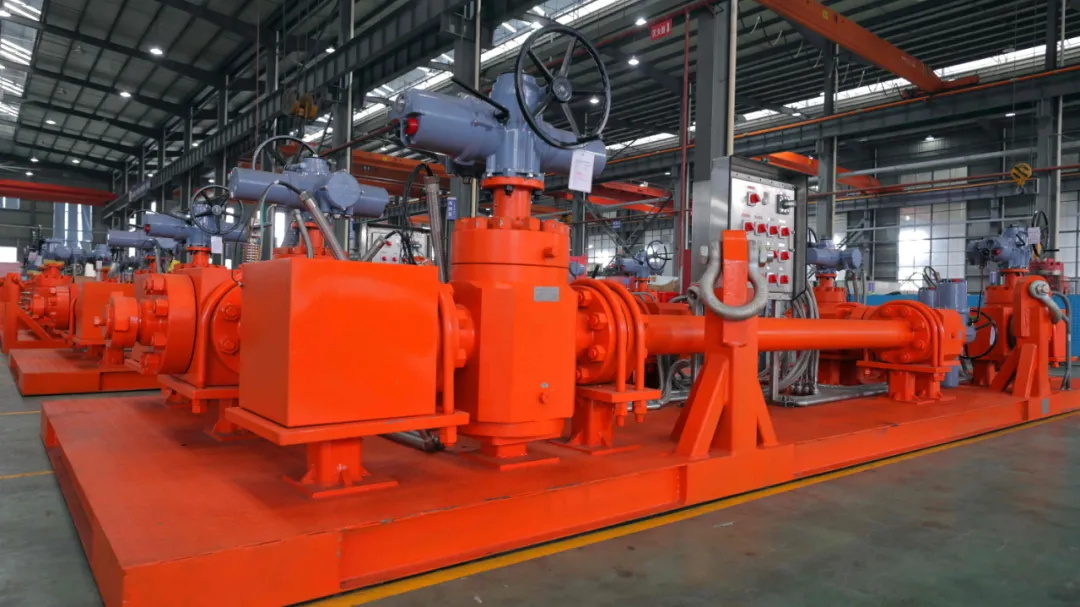

5'' 105MPa High and Low Pressure Manifold

It is used for the transportation, diversion, confluence and circulation of on-site fluid media, which is equivalent to the fluid gathering and transportation and pressure control hub, with reliable performance and good stability.

5''(130mm) 105MPa Universal Joint Assembly

It is mainly composed of a tee and a rotating unit. Under the condition of multi-well installation, there are differences in the installation conditions of different wellheads, resulting in differences in the height and angle of different wellheads. Through the universal joint assembly, the installation differences of different wellheads are compensated, and finally all surface manifolds are kept at the same installation height.

Sewage Manifold

3-1/16'' (78mm) 140MPa Sewage manifold, composed of tee, flanged pipe, choke valve and gate valve; double choke channel design, each with four sets of choke valves. Four-stage choking is carried out to ensure the safety of operation under the working condition of 140MPa. Except for two sets of fixed choke valves, the other choke valves and gate valves are all driven by imported electric drive heads to realize remote control.

Nozzle Manifold

3-1/16'' (78mm) 140MPa Electric nozzle manifold, which is composed of tee, flange pipe, choke valve and gate valve; three choke channels are designed, and each channel adopts a single choke valve, to ensure safe operation under 140MPa ultra-high pressure working condition. Except for two sets of fixed choke valves, the rest of the gate valves are driven by imported electric drive heads to realize remote control.